How to Choose Materials for New Energy Charging Cables

Introduction

With the rise of new energy vehicles and the increasing demand for renewable energy sources, the need for efficient and reliable charging cables has become paramount. Choosing the right materials for these cables is crucial to ensure their performance and longevity. In this article, we will discuss the key factors to consider when selecting materials for new energy charging cables.

1. Conductivity

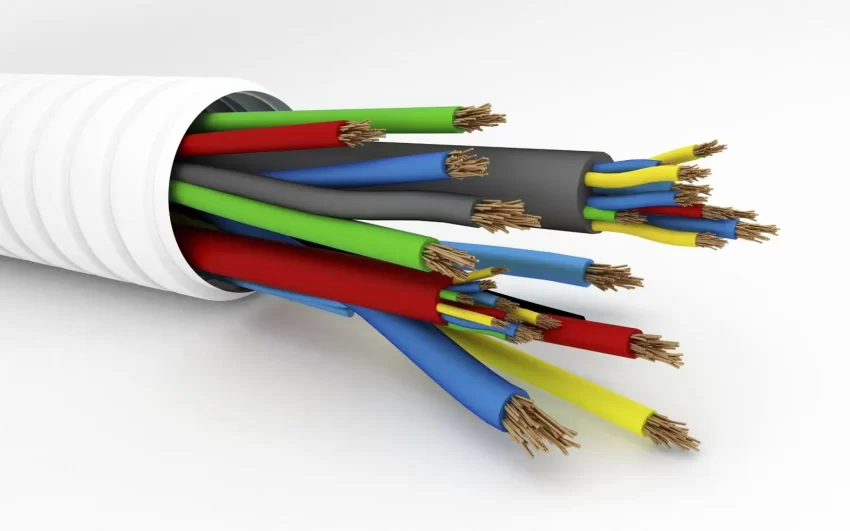

The conductivity of the cable material directly affects the charging efficiency. Copper is widely recognized as one of the best conductors, making it a popular choice for charging cables. However, due to its high cost and weight, copper-clad aluminum (CCA) has emerged as a viable alternative. CCA cables offer a good balance between conductivity and affordability, making them a cost-effective option for new energy charging cables.

2. Durability

New energy charging cables are exposed to various environmental conditions, including extreme temperatures, moisture, and mechanical stress. Therefore, choosing materials with high durability is essential. The cable’s outer jacket should be made of a robust material such as thermoplastic elastomer (TPE) or polyvinyl chloride (PVC). These materials provide excellent resistance to abrasion, oil, and UV radiation, ensuring the cable’s longevity even in harsh conditions.

3. Flexibility

Flexibility is another critical factor when selecting materials for charging cables. The cables should be easy to handle and maneuver, especially during outdoor charging or when stored in tight spaces. Silicone rubber is a popular choice for the cable insulation due to its flexibility and resistance to extreme temperatures. It allows the cable to maintain its pliability even in cold weather, making it ideal for outdoor charging applications.

4. Safety

Safety should never be compromised when choosing materials for charging cables. New energy charging involves high voltages and currents, which can pose potential risks if the cables are not adequately insulated. Insulating materials should have a high dielectric strength to prevent electrical breakdown and ensure user safety. The insulation can be made of cross-linked polyethylene (XLPE) or ethylene-propylene rubber (EPR), both known for their excellent electrical properties.

5. Fire Resistance

Fire resistance is a crucial property for charging cables, as they are often exposed to high temperatures and are connected to power sources. Choosing materials with good flame retardancy is essential to prevent fire hazards. Halogen-free thermoplastic compounds such as thermoplastic polyurethane (TPU) or polyolefin are commonly used for the outer jacket due to their self-extinguishing properties and low smoke generation.

6. Standards Compliance

When selecting materials for new energy charging cables, it is essential to ensure that they comply with relevant international standards. These standards define the requirements for safety, performance, and environmental impact. The most common standards for charging cables are IEC 61851 and SAE J1772 for electric vehicles and IEC 62196 for charging connectors. Choosing materials that meet these standards ensures compatibility and reliability.

Conclusion

Choosing the right materials for new energy charging cables is crucial to ensure their efficiency, durability, and safety. Conductivity, durability, flexibility, safety, fire resistance, and compliance with international standards are all key factors to consider. By carefully selecting appropriate materials, we can create charging cables that meet the demanding requirements of new energy vehicles and contribute to the sustainable future of transportation.