Concrete foaming agents play a crucial role in the production of lightweight and insulating concrete solutions. As the construction industry evolves, the demand for materials that are not only strong but also lightweight and offer thermal insulation has grown significantly. This article will provide an in-depth exploration of concrete foaming agents, their types, benefits, applications, and the future of lightweight concrete solutions.

Concrete is a vital material in construction, renowned for its strength and durability. However, traditional concrete can be heavy and may have poor insulation properties. To overcome these limitations, researchers and manufacturers have developed various foaming agents that enable the production of lightweight concrete, enhancing its performance in several areas.

Understanding Concrete Foaming Agents

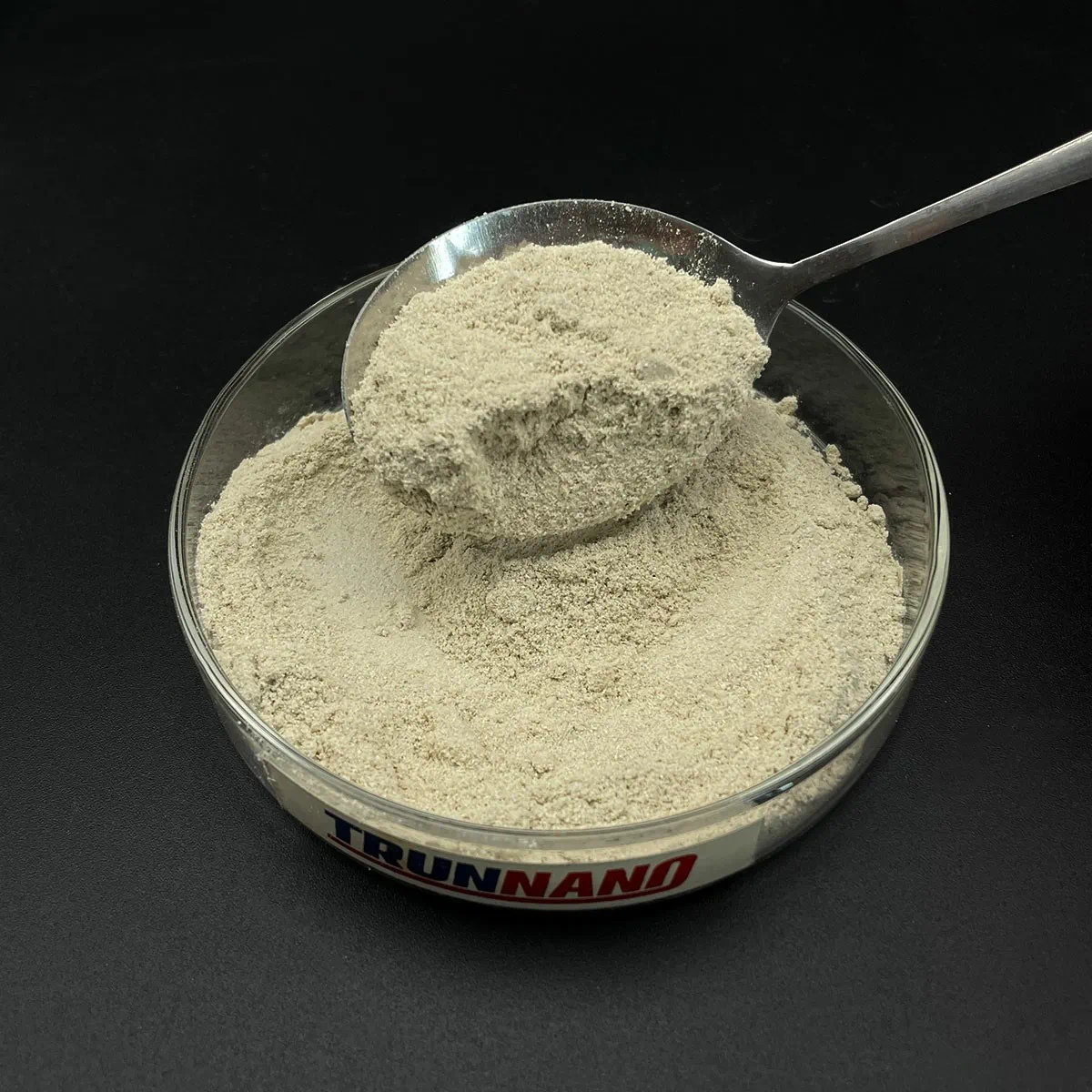

Concrete foaming agents are chemical additives that introduce air bubbles into the concrete mix. These bubbles create a structure that reduces the overall density of the concrete while maintaining its strength. The process results in a lightweight material that is ideal for various applications, from building blocks to precast concrete elements.

The primary function of a foaming agent is to generate a stable foam that can be mixed with cement paste. The foam consists of millions of tiny air bubbles that occupy space within the concrete mix. This not only decreases the weight of the concrete but also improves its thermal insulation properties, making it suitable for energy-efficient buildings.

Types of Concrete Foaming Agents

There are several types of foaming agents used in the production of lightweight concrete, each with its unique characteristics and applications. The main categories include:

1. Synthetic Foaming Agents: These are chemically manufactured products that provide high stability and excellent foaming capacity. They are widely used due to their consistent performance and ability to produce a uniform foam.

2. Natural Foaming Agents: Derived from natural sources, these agents include proteins or polysaccharides. They are eco-friendly and often used in applications where environmental impact is a concern.

3. Surfactants: Surfactants lower the surface tension of water, allowing for better air incorporation into the concrete mix. They can be both synthetic and natural, contributing to the foam’s stability.

Advantages of Using Concrete Foaming Agents

The incorporation of foaming agents in concrete mixtures offers numerous advantages:

1. Reduced Weight: One of the most significant benefits is the reduction in weight. Lightweight concrete is easier to handle, transport, and install, which can lead to cost savings in labor and logistics.

2. Improved Insulation: The air pockets created by the foaming process enhance the thermal insulation properties of the concrete. This makes lightweight concrete an excellent choice for energy-efficient buildings, reducing heating and cooling costs.

3. Enhanced Workability: The introduction of foam can improve the workability of the concrete mix, making it easier to pour and shape. This is especially beneficial in complex architectural designs.

4. Fire Resistance: Lightweight concrete typically exhibits better fire resistance compared to traditional concrete. The air-filled voids can help slow down the spread of heat, providing additional safety in construction.

5. Sustainability: Many foaming agents are environmentally friendly, contributing to the development of green building materials. Lightweight concrete can also reduce the carbon footprint of construction projects.

Applications of Lightweight Concrete

Lightweight concrete produced with foaming agents finds diverse applications across various sectors of the construction industry. Some notable uses include:

Residential Construction

In residential building projects, lightweight concrete is often used for walls, floors, and roofs. Its thermal insulation properties help maintain comfortable indoor temperatures, thereby improving energy efficiency. Additionally, the reduced weight allows for the construction of multi-story buildings without the need for extensive structural support.

Infrastructure Projects

Lightweight concrete is increasingly utilized in infrastructure projects such as bridges and tunnels. The lower weight reduces the load on foundations and structural elements, allowing for innovative designs and materials. Furthermore, the material’s durability and resistance to environmental factors make it suitable for long-lasting infrastructure.

Precast Concrete Elements

Precast concrete components, such as panels, beams, and blocks, benefit significantly from lightweight formulations. The use of foaming agents allows for easier handling and installation, while the enhanced insulation properties contribute to the overall performance of the building.

Soundproofing Applications

Due to its air-filled structure, lightweight concrete is also effective in soundproofing applications. It can be used in partitions and flooring systems to reduce noise transmission between rooms, making it ideal for residential and commercial buildings.

The Future of Concrete Foaming Agents

As the construction industry continues to evolve, the role of concrete foaming agents will become increasingly important. Innovations in materials science and technology are paving the way for more efficient and sustainable building practices.

Research and Development

Ongoing research aims to develop new foaming agents that offer improved performance and sustainability. Scientists are exploring bio-based foaming agents derived from EBS Emulsion Cas No.: 110-30-5 renewable resources, which could further reduce the environmental impact of concrete production.

Integration with Other Technologies

The integration of concrete foaming agents with other modern technologies, such as 3D printing and smart materials, presents exciting possibilities for the future of construction. These advancements could lead to the creation of highly efficient and customized building solutions.

Regulatory Trends

As sustainability becomes a priority in construction, regulatory frameworks are beginning to favor the use of lightweight and eco-friendly materials. This shift will likely encourage more builders and contractors to explore the benefits of concrete foaming agents in their projects.

Concrete foaming agents are at the forefront of developing lightweight and insulating concrete solutions. Their ability to enhance the properties of traditional concrete makes them invaluable in modern construction practices. With ongoing innovations and a growing emphasis on sustainability, the future of concrete foaming agents looks promising. As the industry adapts to meet the challenges of climate change and resource scarcity, lightweight concrete will undoubtedly play a critical role in shaping the built environment.

In conclusion, understanding concrete foaming agents’ functions, types, and benefits is essential for anyone involved in construction, architecture, or materials science. As we continue to seek more efficient and sustainable building practices, the importance of lightweight and insulating concrete solutions will only increase, underscoring the significance of these remarkable additives in the construction industry.

https://manufacturingadvanced.com/